2024/11/04

Improve welding efficiency and select suitable welding materials

Welding consumable materials play a vital role in the welding industry. Choosing suitable welding materials can improve welding efficiency and ensure welding quality. This article will introduce how to select suitable welding consumable materials according to specific needs to obtain the best welding results.

2024/10/30

Exploration of Welding Materials Welding Consumables Knowledge Encyclopedia

Welding consumables are materials used in the welding process, including welding rods, welding wires, flux, etc. Choosing the right welding consumables is critical to welding quality and efficiency.

2024/10/29

Explore welding material Welding Consumables

Welding consumables are materials used in the welding process, including welding rods, welding wires, flow agents, etc., and are an indispensable part of the welding process. Knowledge of welding consumables is essential for achieving an effective welding process.

2024/06/05

Materials and main tools: including welding rods, the model should be selected according to the design requirements. The external wiring of the welding equipment must be firm and reliable, especially the return route of the workpiece.

2024/06/05

Welding standard specification and process

Welding standards and processes are important guarantees to ensure the welding quality during the production and installation of steel structures. The following is a summary of the relevant pages: Scope of application: The standard specifications of welding engineering are usually applicable to the manual arc welding of steel structures in general industrial and civil construction projects

2024/06/05

Generally speaking, the welding process includes the following steps

Welding method selection: Select the appropriate welding method according to the specific situation, such as hand arc welding, submerged arc welding, argon tungsten arc welding, etc.

2024/06/05

The development of the welding process requires consideration of many factors, including the nature of the material to be welded, the choice of welding method, and the structural type and welding performance requirements of the weldment. Generally speaking, the welding process includes the following steps:

2024/06/05

First, the metal at the connection site is heated to a molten state, which is called melting core. When the temperature is high enough, the surface tension of the material being welded is reduced, allowing the molten metal (solder) to wet the substrate and solidify to form a strong contact as the temperature decreases.

2024/06/05

The principle of welding, how to form the solder joint

The principle of welding is based on solid bonding between metals, and the specific formation process involves several key aspects. First, the metal at the connection site is heated to a molten state, which is called melting core. When the temperature is high enough, the surface tension of the material being welded is reduced, allowing the molten metal (solder) to wet the substrate and solidify to form a strong contact as the temperature decreases.

2024/06/05

The principle of welding is the process of binding two or more metal workpieces together by heating them to a molten state and then allowing them to cool and solidify. Depending on the welding method, this process may involve generating enough heat to melt the metal through an electric arc, gas flame, laser, or other heat source.

Related News

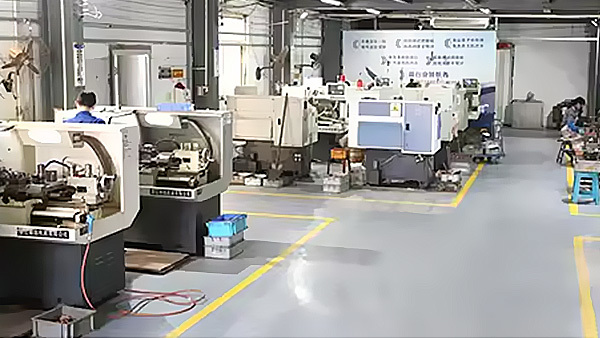

Contact Us

Email:

sonya@shengruipu.com

Hotline:

+86 13393275231

Company Address:

Yancun, Lvgongbao Town, Cangzhou, Hebei, China